The Final Say In Food Safe 3D Printing (UVU Microbiology & Engineering)

- Matt Thomas

- Aug 20, 2022

- 18 min read

Updated: Feb 24, 2025

This is a blog post of my data and findings:) The peer review is in the link below. The first link from researchgate is the extended paper and the second link is the original. The extension covers lead, pigment and other contaminations as well as more tests with pathogens. The extended paper is the more up to date version (PDF) The Impact of Sanitation Methods of 3D-printed Parts for Food and Medical Applications (researchgate.net)

THE ABOVE LINKS TO MY PUBLISHED AND PEER REVIEWED PAPER. THIS PAPER IS AN EXTENSION OF MY ORIGINAL 2023 PAPER THAT WAS PUBLISHED BY IEEE AND GIVEN AT AN IEEE CONFERENCE. ALL CONFERENCE PAPERS ARE PEER REVIEWED BEFORE PUBLISHED. THERE HAVE BEEN MANY WHO THINK THEY KNOW MORE THAN THE SYSTEM AND THE AUTHORS BY STATING "CONFERENCE PROCEEDINGS AND PAPERS ARE NOT PEER REVIEWED." AS PER IEEE

"Peer review is vital to the quality of published research. IEEE requires all conference papers go through the peer review process before publication."

Summery & Scope

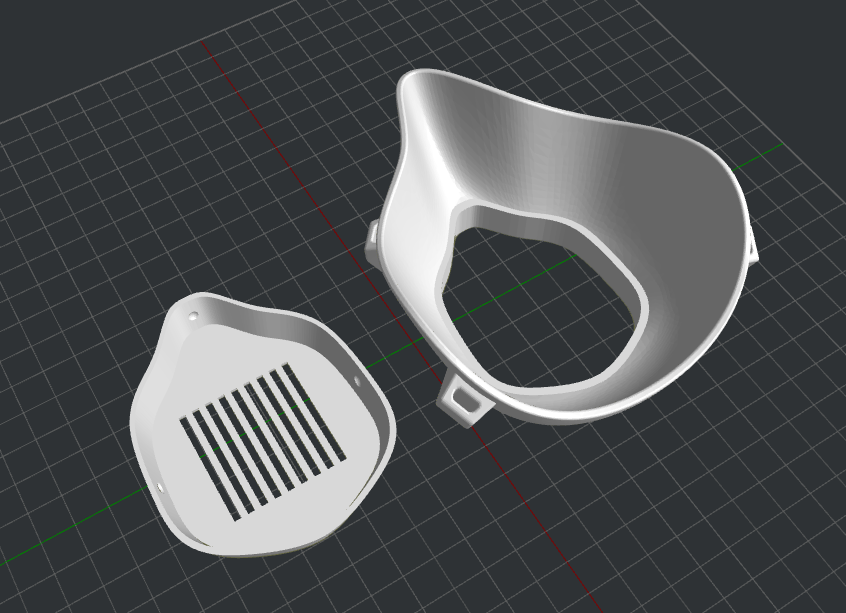

With the rise of Covid and mass shutdowns during early 2020, effecting the production of PPE, frontline workers found themselves in a big mess. Concerned makers decided to take matters into their own hands and 3D print masks and face shields. This brought many questions to the table such as “Can 3D printed parts be cleaned, sanitized and reused for food or medical?” Common sense and instinct say yes, however, it must be documented and approved for hospitals, where lives are at stake, to use 3D printed items. Granted, during the shortage, they used whatever they could get their hands on, including my 3D printed masks and face shields.

Another reason to clean 3D printed parts, what if one of your children is using a 3D printed hand from Team Unlimbited? or you are printing hands for children that are missing hands? We need to make sure they can be cleaned and won't pass on contamination to the recipient or others. And let's not forget that school was cancelled, which means you have all your kids at home, and trying to keep them entertained can be tough. I think more cookie cutters were printed at home during the pandemic than any other time in history. I know many people who printed spoons, forks, straws, cookie cutters, and containers during the pandemic because they had the materials to do so, and it was entertaining when you have nothing else to do. With all these masks, face shields, cookie cutters, and straws, i wanted to make sure they could be cleaned to safe levels.

The scope of this project is to provide an understanding and a methodology to show that 3D printed objects can indeed be cleaned to levels good enough for food and possibly the operating room. Testing methods, findings and all procedures will be documented in this report. One should be able to reproduce my work and prove to themselves that 3D printed parts are food safe and easy to clean. For my chosen method of cleaning, I went with the 200-year-old practice called HAND WASHING. I used basic Dawn dish soap to clean all my printed parts for testing. I then decided to test a more diluted dish soap to see how clean I can get the printed objects. However, to ensure other methods work, I used 70% IPA, as well as the basic wash, rinse, sanitize method used in food establishments and hospitals.

Items we tested were of the following: PLA+, PLA, PETG, 3D printed respirator mask, glass squares for control samples, shirt, cotton mask, metal fork, metal spoon, my fingernails and hands after washing them. The 3D printed mask was cut into pieces to use as samples. I also have some cubes and first layer prints inoculated with Salmonella typhimurium. The 3D printed mask was used for many weeks without washing, so it was plenty dirty. I also let it sit for 3 months in a warm environment to allow bacteria and biofilms to form.

Note; when I mention "wash, rinse, sanitize in bleach water" this means to wash the part in warm soapy water, rinse with warm water, then soak in a cold bleach bath for 2 minutes

Materials and Equipment

To keep things organized, I will just do a basic table list of all materials and equipment:

Petri dishes | PLA/PLA+ filament | PETG filament | Chicken blood |

Vega 3 TE SEM | Home built printer | Autoclave | Hygenia Pro swabs |

Distilled water | The Pathogens | Safety glasses | Gloves/Mask |

Preliminary Information

Soap is a very impressive invention. The use of fats and sodium hydroxide, made from mixing water with charcoal ash, creates a chemical reaction known as saponification. When soap comes in contact with bacteria, be they good or bad bacteria, soap cannot tell the difference, the cell walls breakdown, since they are fat, and are turned into more soap. Now, viruses require a host cell to reproduce and infect others, so you wash away the host cells, then there is nothing there for the virus to attach too. This is why washing your hands during the cold and flu season is so important

The reason soapy water does so well at cleaning objects is due to two reasons, first the surface tension, and second, the nature of soap. Water has a naturally high surface tension, meaning that the hydrogen bonds are strong and allow water to hold its shape. This is why water beads up on plastic or glass. Water does not flow well into small pores. This is known as the “Wetting Angle” If you can loosen the hydrogen bonds a little, water can then flow far better into the pores or cracks of objects. This is where soap comes into play. Soap reduces surface tension by about 65%, allowing the soapy water into pores as small as 0.125 microns, about the size of a virus.

Let us refocus our attention back to the wetting angle. Below are some images describing how a liquid, such as water, beads on a solid surface. As you add different things to the water, surface tension is reduced, by weaking the hydrogen bonds, it’s more like relaxing them.

Soap added to water, yields an almost 0-degree wetting angle. This allows soapy water to flow into pores and crevices the size of bacteria and viruses. This is what makes it such an incredible cleaner. In fact, 70% IPA (rubbing alcohol) has the same wetting angle, and in facilities where filters are manufactured to filter out viruses from the blood, it is required by Federal Regulations to use 70% IPA or higher.

Now, if we were to look up some actual data on how much force the surface tension is of water, soapy water, and 70% IPA, you will see that soapy water and 70% IPA have almost identical numbers:

This is important to note. In the next image, you will see how well 70% IPA wets a filter material of 0.100 microns. That is smaller than a virus, meaning, that soapy water can indeed flow into spaces as small as viruses. However, viruses do not work this way. They require the use of host cells in order to reproduce and infect other hosts. We only care about pore sizes above 0.2 microns in width and 1 micron in length. That is the smallest size of bacteria, others are much larger. Below is a figure demonstrating the wettability of IPA.

As you can see, the wettability of IPA 70% is extremely high due to its low surface tension force of 23 dynes/cm. The low surface tension force is what allows a fluid to flow. Knowing this, we know that soapy water has a very low surface tension as well, meaning it is comparable to IPA 70% for flow and wettability. Armed with this information, we know that soapy water can flow into pores as small as 0.1 microns, the size of a virus particle. Bacteria are only 0.5 microns in size which means soapy water will have no issues cleaning out bacteria. This is why under extruded parts are easier to clean than perfect parts. hence why all my testing was done with the best prints i could make. However, I also tested low quality and mid quality parts as well.

Some have asked if IPA can weaken 3d printed parts. For PLA, PLA+, and PETG, the 3 most common thermoplastics, there is no change with their strength after a 12,24, and 48 hour soak in 70% IPA. CNC kitchen has tested this and posted his results on YouTube.

Where a potential problem could exist, is the formation of biofilms. These films are like a protective blanket bacteria put over themselves. These biofilms can form if you do not wash the parts or even household items within a day or so. I am still conducting tests on these possible issues. However, i have found that scrubbing with baking soda and soapy water works well to remove biofilms from dishes and plastics. Baking soda is abrasive enough and is a base rather than an acid. This helps in the removal of biofilms. Below are some sources about baking soda and biofilms: "Baking soda makes an excellent cleaning agent when you need to get rid of biofilm. This is on account of the fact that it works by both chemical and physical means. The rough particles in the baking soda will dislodge any biofilm from the plumbing surfaces, while the basic pH will also help in chemically removing most of the waste. It’s very simple to use baking soda for this indication; you only need to wet a rag, put a bit of the baking soda in it and then scrub away. In no time, you will have cleared most of the slime."

Baking soda can also help inhibit future growth of bacteria and biofilms. A study done by the University of Budapest in conjunction with Sandiago school of medicine shows that baking soda can inhibit the growth of even very tough and dangerous respiratory bacteria such as Pseudomonas aeruginosa, which is one of the bacteria i cultured for my testing.

A wash, rinse and sanitize in bleach water for 2 minutes will in fact dissolve biofilms to safe levels. Even though soapy water does remove biofilms, adding that extra step of safety that only takes 2 minutes, is well worth it. One tablespoon of non-splash-less bleach to one gallon of cold water is perfect solution for sanitizing.

The next set of information is on 3D prints themselves. A lot of people in the 3D printing community have made posts or web articles about how the porosity and layer lines of prints house bacteria and therefore cannot be cleaned. This is a myth and is not true based upon the information of low surface tension cleaning as stated above.

Even under a Scanning Electron Microscope, you can see that there are no pores in 3D prints. There are layer lines, cusps, and dimples, but not pores. Layer lines are 10 microns in width and about 10 microns deep. This is very large in the grand scheme of things, about the Grand Canyon large. Can water still leak between layer lines? yes, yes it can, but remember, water has a HIGH surface tension, so if water can flow through the print, imagine what a low surface tension fluid like soapy water can do:)

Another fun fact, a 2 walled print from various printers held water for 4 days before any leaks were detected under STP conditions. A 3 wall print held water for over 7 days with only evaporation effecting it under STP.

The smallest dimple is 0.5 microns in size. These small dimples make up about 1% of the flaws in prints, the other 99% of flaws are greater than 1 micron. Again, we do not need to worry about bacteria living in the dimples, or layer lines due to the nature of soap. Where bacteria can go, soapy water can go as well.

If dimples or scratches are a concern, then we would, and should be concerned about our own utensils, cutting boards and plastic ware at home. Hereis an image from a digital microscope of a fork. Notice how scratched, dinged, and beat up it is? Now compare that to the SEM images of 3D printed parts. Again, remember, under extruded parts are not an issue, nor are poorer quality parts. They may not hold liquids very well, but they are far easier to clean. Coating in resin/epoxy is best bet if you want to hold liquids, and yes, its food safe according to title 21 volume 3 of the fda. More on this later

Let’s talk about the nozzle and other components. The amount of lead in a brass nozzle is about 1.5% for a standard 3 gram, 0.4mm nozzle. It will be less for larger bore sizes since material was removed.

1.5% of 3 grams is 0.045 grams of lead. Now, 21% (0.63 grams) of a 3 gram standard 0.4mm nozzle is removed for the filament to flow into as indicated by the photo below. This also means that 21% of the 0.045 grams of lead were removed as well, leaving a total number of 0.035 grams of lead remaining in the TOTAL nozzle. This means even less is in contact with the filament as it passes through. The filament is only in contact with 21% of the TOTAL amount of lead, which means a total possible contact with 0.007 grams of lead. Now lead leaches out in very small amounts, and usually from handling, or from water sitting/flowing through a brass fixture. The possible amount of lead being leached, or friction rubbed onto filament is very low. You will get more exposure to lead from changing your nozzle then from the filament. In fact studies done have shown that consumers who use the standard brass key, are exposed to 19 times the safe amount of lead. A more dangerous exposure to lead is from shooting due to it being vaporized. I love to shoot so i guess im gonna have to be careful. Masses of new nozzles compared to used nozzles (1000 hours of use) show that either no mass was lost due to printing, or the amount lost due to friction was so small, that the scale did not pick it up, meaning, such an extremely small amount of lead had been friction rubbed onto the thousands of meters of filament over 1000 hours of use. I

**State conducted studies found the average exposure level for the lead residue on the hands of consumers handling brass keys was 19 times the Proposition 65 “No Significant Risk Level” of 0.5 μg per day limit**

Ingested SMALL amounts of inorganic lead from the nozzle, reacts with stomach acid to form insoluble lead chloride, which then passes through the gut or urine, however, this does not mean to go grab some lead and start eating it. Lead poising is a real and very threating condition. The aluminum from the other parts is no issue since we use aluminum in 99% of our cooking needs such as foil, pans, forks, spoons, etc.

There is more lead in your tap water than a full 3d printed part. The area the food touches is not that much surface area, and the amount of lead in the area food touches is extremely low since it is a fraction of the 0.007 grams that could potently leach into the part.

Testing Methodology

For testing, 2 approaches were chosen: pathogen culture and Protein testing. Cultures allow us to physically see how many colonies have grown and to calculate if it is safe. The second method is to use protein swabs. These test for blood proteins, along with other proteins that are left from food, blood, or other organic matter, to see how clean a surface is. Blood proteins are the hardest to remove from surgical tools and they can carry very dangerous prions or infectious pathogens with them. Proteins are the main component of viruses as well, so ensuring their removal allows for a very clean environment. If a protein has been denatured via heat, they become especially hard to remove. Using these 2 gold standard methods for testing how clean hospital surfaces are, we can determine if 3D printed parts can be cleaned to safe levels. Some feel that labs are cleaner and more sterile than home kitchens, that is true, however, the amount of bacteria that i cultured and inoculated the 3D printed parts with, is far FAR above what you would see at a home kitchen, and far more dangerous. Pseudomonas is a very deadly bacteria that causes major respiratory shutdown, blood infections, and among other things. I would not want to bring this into any persons home for testing. If one is interested, here is the list of pathogens I cultured in lab:

Klebsiella pneumoniae

Acinetobacter baumanii

Pseudomonas aeruginosa

Escherichia coli

Shigella sonnei

Salmonella typhimurium

Proteus mirabilis

Citrobacter freundii

Bacillus cereus

Streptococcus pyogenes

Print Settings

I used two different printers for the experiments; Tevo Tornado gold edition and 2 home built machines I built from random parts. Even using a cheap Anet A8 or a printer with massive under extrusion is not an issue, remember, that soap can flow into very small spaces, so large under extrusions or layer gaps are not an issue, plus, who wants to have bad prints anyway. All my printers have gone through very basic calibrations that ALL printers should go through before printing anything. I have made sure esteps are correct, as well as flow, and xyz steps. 0.16mm layer height to 0.24mm layer height in increments of 0.02mm 40mm/s to 70mm/s in increments of 5mm/s

205C to 220C in 5C increments Bed temp always stayed at 60C 3 test pieces had 1 wall, 3 had 2 walls, and the last 3 test pieces had 3 walls

Cubes were hollow to hold liquids, mainly chicken blood since that is available to home users

All cubes were inoculated, tested, and imaged with the Vega 3 Scanning Electron Microscope, and all yielded the same results listed in the testing section. The final tests were done with a single wall, a double wall and a triple wall of all 3 flavors of filament, using 0.16mm layer height and 60mm/s

Procedure

The first set of petri dishes, I was testing to see how well basic soap and water cleaned the surface of 3D printed parts and how deep the soapy water got into the object. I took my NIH approved 3D printed 2- part mask I have been wearing for 16 months, in which I have purposely not sanitized it for 3 months. I swabbed it, then prepared the dish, and incubated it for 7 days of growth.

I then separated the mask into its two counter parts, washed (no scrubbing with a brush) one with soapy water (120F). Before washing I made sure that the swab contained contamination from both parts of the mask, not just one. The results are below:

From visual inspection, you can see that there has been roughly a 90% reduction in bacteria, this is good. This keeps it below the ID (infectious dose) number. The ID number is specific to the bacteria being tested. IE, a certain amount of salmonella will not make you sick, but if you go past that number, chances are, you will get ill. To put this in context, lets look at a sample of my clean washed shirt after i went to a few stores:

In pathogen culture, the gold standard and preliminary tests to hospital and food safety, there is a formula for Colony Forming Units (CFU) or Plaque Forming Units (PFU) that we use. Its calculated based on the amount of cultured broth that is used to inoculate a petri dish. In the lab, we made all of our own broths and petri dishes. That's part of the fun, its tedious, but fun.

Visual inspection is not nearly good enough for hospitals or food establishments. So, we must use other testing methods to determine how clean they are. Using an ATP monitor (very expensive) you can test how many light (usually IR) units reflect to the monitor. A more reasonable method is to use the ATP swabs. ATP is Adenosine Triphosphate and every living cell uses it as its energy source and they leave it behind as they move about. So what about dead or non-living cells and contamination from microbial organisms? Syscehm, a UK company states the following:

“ATP Hygiene monitoring does not represent contamination itself. Therefore, microbial or organic contamination will always be an indirect measurement when measured by ATP. On the other hand, however, Protein Residue tests directly measure organic/microbial contamination.” This is why i am using the PRO-Clean protein residue swabs. They are the most accurate form of testing. More on this later.

Now, we need to test consistency of IPA and soapy water, I used a couple of controls. The first set were 1 inch by 1 inch glass tiles. They were sanitized first, then I just handled them with my hands and fingers to place some bacteria on them. This simulates putting dishes away, or grabbing a glass bowl with your hands, then changing your mind and putting it back in the cupboard. I was really surprised to see how much bacteria grew after 4 days in my petri dishes

The next step is to clean the tiles with IPA and soapy water. The water used in all the tests has been the same temperature, 120F. This helps keep consistency in my experiments so that the data can reflect accuracy and precision. After the tiles were cleaned, I waited 3 minutes for them to air dry, then swabbed them. As you can see, both sanitizing agents worked very well.

Comparing these results to the above 3D printed results, we can see that the glass has fewer colonies of growth, which is what I wanted to show. Glass is the best container to use for food, and other items because its porosity is very low and is difficult for bacteria to cling too.

In the figures below, you can see that soapy water left no growth, but the IPA had 2 colonies of bacteria forming. This is well below the Infectious Dose number and could be error due to not sanitizing the entire section of glass.

The same procedure was then repeated but using the protein residue swabs to test the 3D printed mask that I had inoculated with Salmonella typhimurium 2 hours previously. In the image below, you can see the control swab and how it has turned purple, this indicates an abundance of proteins. I then washed samples of 3D printed parts with Salmonella in just warm water so that I could take a protein swab test for a control. The test turned purple since water was not able to wash all residues away.

Let us compare results after washing a second piece of the mask with basic soap and water as well as some cubes and first layer prints that have been inoculated with Salmonella typhimurium as well. No alcohol was used for the second set. We want to see how well basic soap and water can clean items since during times of pandemics, rubbing alcohol (IPA) or even bleach can be very difficult to come by.

**A note on bleach. Do not use splash-less bleach to clean. It is not the same as regular bleach that contains sodium hypochlorite

The printed parts were tested at 2 hours and 24 hours after cleaning. The control is shown against the green solution. Green is clean. No proteins after 2 and 24 hours after cleaning with basic soap and water. This means nothing was left behind to allow pathogens to grow and multiply. If they were to grow, they would leave behind new contamination which the protein swabs would pick up.

I confirmed my findings with another tester, who did a wash in soapy water, rinsed the part, then sanitized it by soaking it for 5 minutes in bleach water at the hospital. The 5-minute time frame was to allow the bleach water to seep into the part. The surgical technician then did an ATP and protein swab test. They found the parts to be well within spec and useable for a medical setting.

I wanted to further test the 3D printed parts to really see if I could get the bacteria into very small spaces. I printed up a 2 wall print with 0.5 extrusion width for both walls. The layer height was 0.24mm and printed at a speed of 60mm/s and a temp of 215. This particular cube held water under pressure and did not leak. This was frustrating because i wanted it to leak. However, i continued to test.

I filled the cube up with pure chicken juice and blood. I did this because this is what most conditions in a house will be like. In a lab, we are using very dangerous bacteria, but in a controlled environment. I wanted to test this at home under average conditions, and even the worst conditions.

I spread some of the liquid around the entire print and allowed it to soak in the juices as well. I removed it and allowed to dry for 36 hours. This allowed plenty of time for bacteria and biofilms to form. I then cleaned the part with warm soapy water from a foam dispenser type. I used just my fingers to scrub, no brush. I then allowed the part to air dry and then tested using the protein residue testing swabs. I tested the inside and outside of the part THOURGHLY. The results came back CLEAN and passed all tests. To further test, i added clean distilled water to the cube and added pressure to it. This allows the water to become contaminated with proteins IF any are still present, by squeezing the water into the smaller spaces. The water came out clean. I am going to test again, but this time with a cube that WILL leak.

Conclusion

After much preparation, and testing, and I will continue to test more and more because, why not? I have concluded that 3D printed parts can be cleaned to operating room standards. Does this mean they are food safe? Yes, and a small no. Yes, because they can be cleaned and can hold dry foods with no issues. Possibly No, because with liquids, they can cause the color additives and binders used in the filament to POSSIBLY leach out. It is rare, but still possible. Also, if the 3D printed item is to hold liquid, it is best to coat in resin and epoxy as stated above.

Now, when it comes to medical devices, 3D printed parts hold up well. Masks, valves, and other parts can be cleaned and cause no contamination. If using parts for medical, please do a bare minimum of wash in soapy water, rinse, and soak in cold bleach water for 2-5 minutes.

If you want super clean, wash with warm soapy water and a little baking soda, then rinse and sanitize.

To be safe, and this is my lawyer talk, it is best to coat a 3D printed object for liquids in resin. According to title 21 of the FDA, resins are food safe after a full curing time. This is because the primary bonds that occur during curing have reached a point where they are unavailable to be reactive with food or other items.

New Information:

During the manufacturing process, pigments are added to the melted plastic. Companies, to keep their color a trade secret, will avoid using any type of pigment that requires a listing on the MSDS therefore, pigments used in filaments are usually non-toxic and inert to most treatments and foods. However, to avoid any possible risk, coating in resin adds an extra step of safety. In most cases, the color of plastic does not bring any danger or changes the properties more significant than changing its melting point. As the chosen pigments are inert to most treatments, they do not need to be listed on the MSDS, and thus omitted, allowing the companies to keep them a trade secret that helps them compete against other companies for only they have this one specific color

The real question is, is it worth 3D printing food wares? Granted it's fun and cool, but its more expensive and very time consuming. A plastic bowl at my local box store is 50 cents. To 3D print a bowl is 12 hours of electricity, plus $1.5 worth of filament.